Automatic lubrication systems provide your equipment with the perfect amount of lubricant at the perfect time, even when your equipment is in operation. But how do these handy systems actually work?

Let’s take a look at each of the different parts of a typical automatic lubrication system. Want to learn more about automatic lubrication systems? Learn from the experts here at LH Travis.

Parts of an Automatic Lubrication System

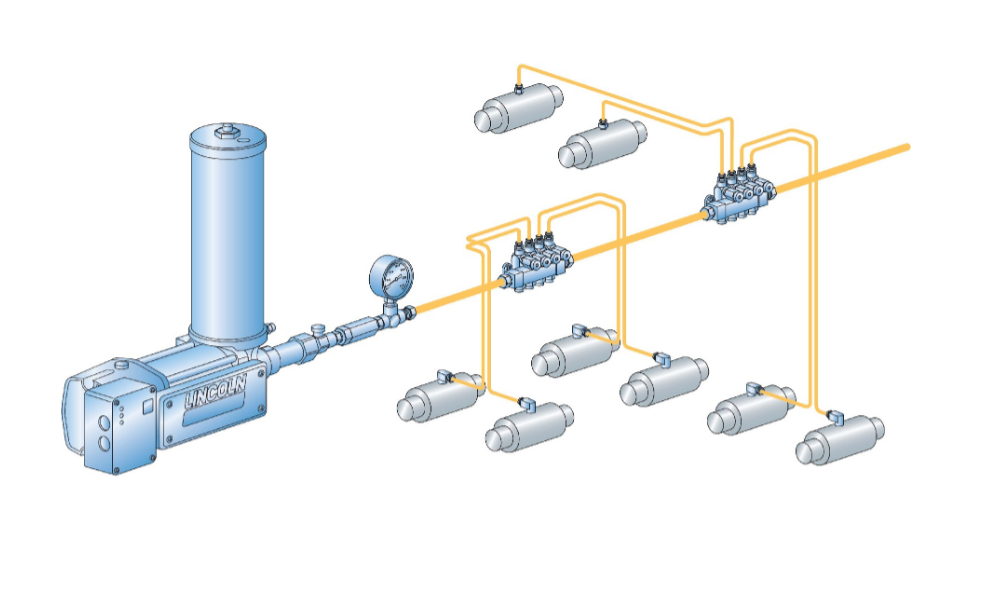

While automatic lubrication systems can come in multiple configurations, such as single-line parallel systems or series progressive systems, the basic components are largely the same. A typical automatic lubrication system will consist of:

- A pump and reservoir

- A controller

- Metering devices

- Hoses and fittings

- Accessories

Let’s take a closer look at each of these components.

- Pump and Reservoir

This part of the automatic lubrication system is what stores the lubricant (in the reservoir) and distributes it in a steady flow (via the pump). Different systems and lubricant types will use slightly different pumps. For example, there are different pumps for grease versus oil, and a variety of pump sizes to handle different sized lubrication jobs. - Controller

The controller is the brains of your automatic lubrication system. It activates and monitors the system to ensure proper lubrication. Controllers can be time or cycle based, and track things like cycle completion, high system pressure, low lubricant levels, and low pressure, among other things. - Metering Devices

Metering devices ensure that the perfect amount of lubricant is applied to each lubrication point, every time. These are designed to be accurate, reliable, and durable, even during long runs, under high pressure, and while providing continuous lubrication. - Hoses and Fittings

As you might be able to guess, the hose of an automatic lubrication system is what transports the lubricant from the reservoir to the lubrication points. Fittings are used to attach the hose to the different points of the system. - Accessories

A variety of accessories can be used with automatic lubrication systems to accomplish a variety of different tasks. These can include things like additional monitoring, automatic shut-down, low level switches, and various performance indicators.

Need More Insight?

The different parts of an automatic lubrication system work in tandem to provide consistent lubrication, every time. If you’re interested in automatic lubrication systems for your equipment, contact us today and let our lubrication specialists help you.